This is an old revision of the document!

Sprinkler Solenoid 24VAC Woes

I have had many problems with my sprinkler system; decrepit failing 30 year old underground wiring, failing solenoid valves and their solenoids. Some of the old solenoid valves were replaced as they had mechanically failed. The multiple issues made it vary difficult to diagnose what was happening at any time.

I ended up replacing the wiring twice. The second time I used more robust sheathed multi core wiring and node control boxes with LED lights that confirmed power to each solenoid at the node. This helps easily determine if the fault upstream or downstream the node point.

Basically at this stage the outstanding problem was the just failing valve solenoids. Interesting only the new valve solenoids were failing. The 30 year old valve solenoids and the pump contactor continued working without problems. I tried 3 different new solenoid valve types and all the solenoids failed, within 1 week, to up to 6 months.

I have been using the Open Sprinkler V2.0 since about 2014, this is a 24VAC controller. I reached out to the solenoid valve supplier and asked them if they had any similar such problems. They indicated that some of the open source controllers were DC or perhaps allowing DC offset on to the valve solenoids. This did not make sense in my case the controller circuit diagram clearly shows the output was a solid state AC relay output and the power supply was 24VAC transformer rated to 1 Amp. Also why were only the new valve solenoids failing and not the old valves and pump contactor? The supplier kindly sent me 4 replacement solenoids.

I reached out to the Open Sprinkler about the matter however they did not seem to understand and indicated that the controller was a 24 VAC type and DC was not an issue.

To knock this on the head I purchase a single channel digital oscilloscope and tested the voltage at the controller and the node boxes closer to the solenoid valves. The operating measured voltage was between 25.8 and 25.2 VAC RMS. The wave form was very sinusoidal and the offset was negligible, about 0.2 V. On this basis the whole DC issue was closed out as not applicable in my case.

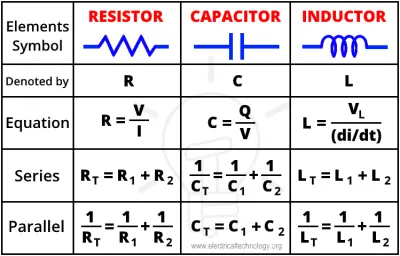

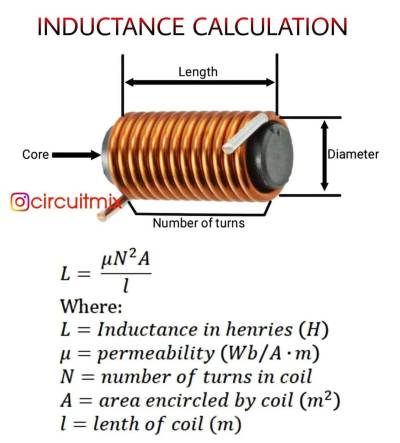

Next I measured the DC resistance of a new solenoid at 33.1 Ohm. Based upon the specification printed on the Solenoid 24 VAC, 50/60 Hz, Holding 0.25 Amp and inrush 0.43 Amp maximum I calculated the solenoid impedance to be 96.0 Ohm. This means the solenoid holding reactance calculates as 90.1 Ohm. The solenoid apparent power is 6.0 VA and real power 2.07 W. With 25.2 VAC supply at the solenoid this becomes 0.264 A current, 6.68VA apparent power and 2.3 W real power. Reactance has the following relationship with Inductance and frequency, XL = 2π F L, where XL is impedance (Ohm), F is frequency in Hz, L is inductance in Henry. So the with 60Hz the solenoid effective impedance increase from 90.1 Ohm at 50 Hz to 108.2 Ohm. At 24VAC 60Hz the solenoid current then drops to 0.21 Amp (was 0.25 Amp at 50Hz) with apparent and real power dropping to 4.87 VA and 1.49W. On my system with 25.2 VAC at the solenoid calculated that adding a 12 Ohm resistor into the solenoid circuit reduces the at solenoid voltage to 23.9 VAC and current to 0.249 AMP. The voltage drop across the resistor is 3.2V and power drop 0.79 W. The resistor was rate at 1 W operation. A USA based brochure for the K-Rain Valve KR7101 gives the following specification for the valve: Voltage: 24VAC 60 cycles, 0.4 amps in rush, 0.2 amps holding. Pressure 20 psi minimum to 150 psi

I measures the voltage across the resistor with the Oscilloscope at between 2.81 to 2.88 VAC RMS and resistor was measured as 12.1 Ohm, so circuit current is calculated at 0.232 to 0.238Amp. This places the solenoid operation back into name plate specification range.

I measure the voltage across the resistor when operating an old solenoid valve and it was 3.03 VAC RMS, with calculated current of 0.25 Amp. Interestingly the wave form across the resistor on the new solenoids looked distorted, more triangular, whereas the old solenoid valves wave form was much more sinusoidal.

As of writing I have only been running the system with the resistor for about 2 weeks. I had to replace 4 solenoids in a 3 month period so it will be interesting to see if this resolves the new solenoid failure problem.

About 6 months earlier the control wire to the pump contactor failed and I needed to get it replaced. It used speaker wire and I replaced with sheathed multi core cabling rated for 24VAC sprinkler applications..

In summary:

- Old decrepit failing underground solenoid wiring replace with new with node boxes fitted and operation well for 4 months.

- New solenoid valve are dual rated for 50/60Hz and rely upon the reactance that varies solenoid current and power draw. In 50Hz applications the current and power draw are higher and the solenoids less tolerance to over supply voltage. Hopefully the resistor will solve this problem.

Lessons learnt to date:

- Multi faceted problem solving is significantly more difficult than single point failure analysis.

- Avoid the use of single sprinkler wiring in more complex larger sprinkler reticulation systems. The use of quality multi core cabling provided a much more reliable system.

- I do not like jar top style valves

- An inductor instead of a resistor may be more effective solution to reduce the solenoid current, however resistors are cheaper and easier to get and also smaller. The power loss is < 1W.